Testing Emergency Response Equipment is Essential

The success or failure of the tools and equipment used in an emergency response can sometimes mean the difference between life and death. For Ziamatic – a leading manufacturer of emergency response equipment and tools, product efficiency and safety start with product testing. Ziamatic rigorously tests many of its products to make sure they perform to the strictest of industry standards.

“Ziamatic does not just test product to comply to the entities that suggest regulations, we test our product for life expectancy, durability to withstand normal use, and durability to withstand product abuse,” said Keith Creely, VP of Ziamatic. “We don’t stop there. Ziamatic’s engineering also tests the competition’s product to see how it stands up next to ours. In most cases, we surpass the competition in retention and testing methods. This is why we promptly provide our own certification in writing when asked.”

There are several entities in the emergency response industry that suggest compliance to a particular standard. Within the fire industry, the National Fire Protection Association (NFPA) establishes safety guidelines for fire departments. Within the EMS industry, the Society of Automotive Engineers (SAE) provides safety guidelines for ambulances and EMS workers.

When it comes to firefighting products, Ziamatic tests SCBA retention and other equipment found in crew areas. Stepping surfaces must pass a slip test and are also suggested to retain static loads of 500 lbs. or more. On the EMS side, Ziamatic tests pressurized oxygen cylinder brackets and fire extinguisher brackets. This is an important safety consideration because crews and patients in an ambulance could be seriously injured if equipment comes loose.

Currently, the NFPA suggest that SCBA or pressurized cylinders, need to be retained to 11 g forces (if mounted in the crew area) to comply. The association also suggests that tools and equipment be held to 9 g forces or more. SAE suggestions vary a bit from product to product. The SAE does suggest that pressurized cylinders need to be retained without issue up to 26 g forces

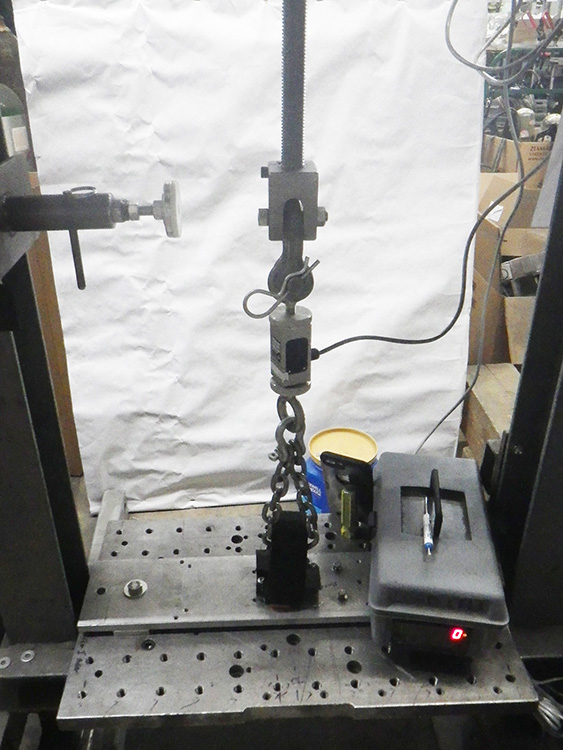

Ziamatic performs several different types of tests. Dynamic load testing and static load testing are common. With dynamic testing, Ziamatic uses a cart outfitted with sensors that indicate loads in specific areas. During the test, the cart is drawn back with elastic cords and then released quickly towards a fixed ridged surface where it crashes. Data is recorded. With static load testing, a steady load is applied to a certain product with mounted equipment. It is then pushed or pulled in different directions. Its load is then calculated. For example, the brackets for the Adjustable Sure-Grip were tested with hundreds of pounds of load. The straps were also tested for effectiveness after heat and ultraviolet exposure.

Some compliancy tests could take months or longer to finalize. It all depends on the type of the product being tested. During the tests, data is documented and video is often taken. This gives Ziamatic documented proof, but also provides a good way to evaluate the testing frame by frame. If a product fails testing, engineering reevaluates and redesigns until all testing is successful before going to production.

About Ziamatic Corp.

For over 50 years, Ziamatic Corp. has provided first responders with the tools and equipment they need to make their jobs safer, easier, and more efficient every day. For more information, please call 1-800-711-FIRE or visit www.ziamatic.com